Hydraulic Breaker patasi Mchimbaji Blunt Wedge Diamond Point

Maelezo ya patasi

Kwa wasambazaji wa malighafi wanaopendelea, nyenzo za 40Cr na 42CrMo huchukuliwa kuwa chaguo za ubora wa juu.Nyenzo zote mbili zina sifa nzuri za mitambo na uimara na zinafaa kwa matumizi fulani ambayo yanahitaji nguvu ya juu na upinzani wa juu wa kuvaa.Kwa upande wa matibabu ya joto, vifaa maalum vya matibabu ya joto vilivyoboreshwa vinaweza kutumia michakato ya juu na vifaa ili kuhakikisha ubora na utendaji wa vifaa.Kupitia michakato mitano ya matibabu ya joto, pamoja na ukali wa hatua mbili, kina cha safu ngumu kinaweza kuongezeka kwa ufanisi na ugumu na uimara wa nyenzo zinaweza kuboreshwa.Kwa njia hii, maisha ya huduma ya bidhaa yanaweza kuongezeka kwa 30% hadi 80%.Maboresho haya yanaweza kufanya nyenzo za 40Cr na 42CrMo ziwe za kudumu na thabiti zaidi.Wakati wa kuchagua wasambazaji wa malighafi, hakikisha kwamba nyenzo ni za ubora wa juu na zinakidhi viwango, huku michakato iliyoboreshwa ya matibabu ya joto inaweza kuimarisha zaidi utendakazi wa nyenzo.

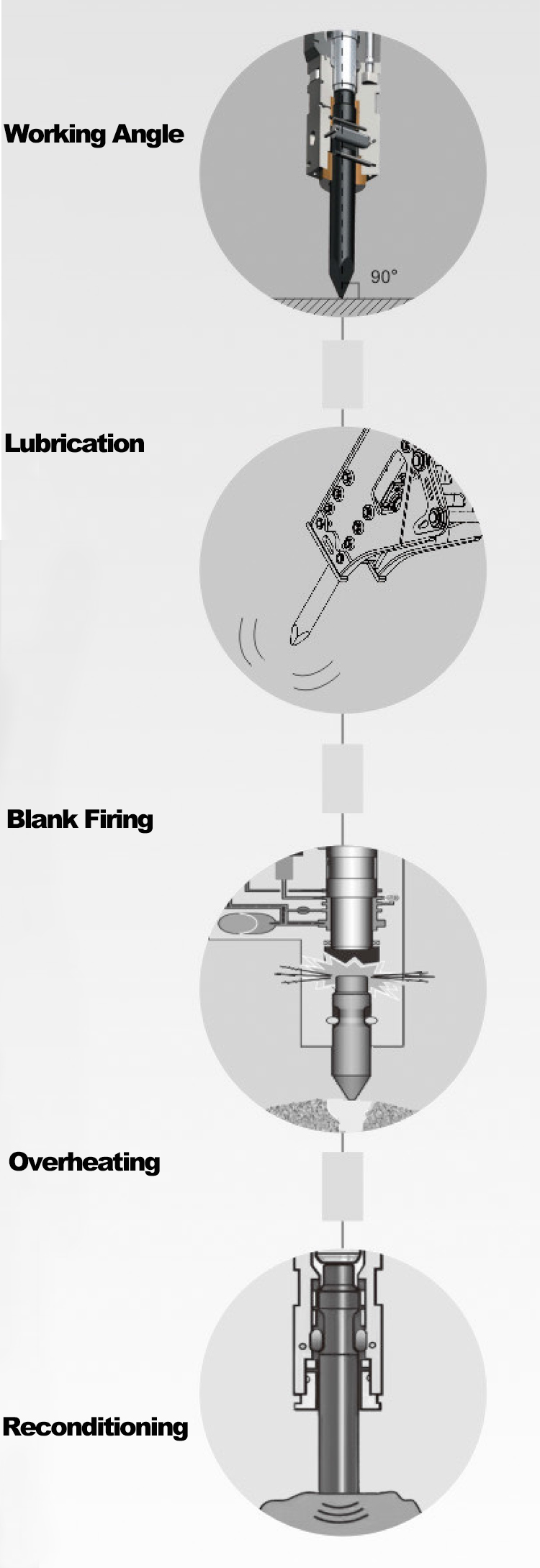

Angle ya Kufanya kazi

operesheni ya mgomo wa wima Ni sahihi kufanya fimbo na uso wa kazi perpendicular kwa angle ya 90 °, ili kuhakikisha maisha ya huduma ya fimbo.Ikiwa pembe si sahihi, shinikizo la juu litakua kati ya fimbo na bushing, na kusababisha kuvaa kwenye nyuso za mawasiliano na uharibifu unaowezekana kwa fimbo au bushing.Misitu iliyovaliwa inaweza kusababisha tilt ya fimbo na uharibifu unaofuata wa pistoni.

Kulainisha

kulainisha Mara kwa mara tumia mafuta ya kulainisha ya hali ya juu ya hali ya juu na yenye shinikizo la juu ili kulainisha uso wa mawasiliano kati ya fimbo na bushing.Mbinu zisizo sahihi za kufanya kazi, kama vile kugonga kwa pembe, kupenyeza kitu au kupinda kupita kiasi, zinaweza kutoa mikazo ya juu kwenye nyuso za mguso.Mafuta hutoa ulinzi bora na kupanua maisha ya huduma.

Kurusha Tupu

Hit kavu Mapigo kavu yanaweza kutokea wakati fimbo haiwasiliani kikamilifu na uso wa kazi, inateleza kwenye kitu kilichovunjika, au kitu ni laini sana au nyembamba.Fimbo inaweza kugonga pini ya kubaki, na nguvu ya athari inaweza kusababisha kuvaa au kuvunjika kwa pini.Inashauriwa kukagua pole mara kwa mara, ikiwezekana kila masaa 30-50, kuangalia uharibifu na kurekebisha kasoro yoyote.Pia, angalia misitu kwa kuvaa au uharibifu na ubadilishe au urekebishe inapohitajika.

Kuzidisha joto

Halijoto ni ya juu sana na hali ya uyoga inaonekana Epuka kugonga nafasi moja mfululizo kwa zaidi ya sekunde 10-15.Kupiga kwa muda mrefu bila kuvunja kitu kutazuia joto kutoweka ndani ya kichwa cha klabu.Wakati joto nyingi linapoongezeka, vijiti vinaweza kuharibika na kuwa laini, na kusababisha uyoga au makundi.Matokeo yake, maisha ya huduma ya fimbo yatafupishwa au inaweza kuhitaji kufutwa.

Urekebishaji upya

Matengenezo ya mara kwa mara Kwa ujumla, fimbo hauhitaji ukarabati.Hata hivyo, deformation ya kichwa husababisha matatizo ya juu juu ya uso mzima wa mawasiliano kati ya fimbo na mvunjaji.Inashauriwa kuitengeneza kwa kusaga au kugeuka.Kulehemu au kukata mwali haipendekezi kwa kuwa joto linalozalishwa linaweza kusababisha mabadiliko ya muundo wa nyenzo na kuharakisha uchakavu.

Chisel Model tunaweza ugavi

| Chisel ya kuchimba | |||||||

| Nyenzo: 42crmo | |||||||

| Mfano | Dia | Urefu | Uzito | Mfano | Dia | Urefu | Uzito |

| SOOSAN | FURUKAWA | ||||||

| SB43 | 75 | 740 | 23 | HB100 | 55 | 500 | 9 |

| SB50 | 100 | 1050 | 58 | HB200 | 70 | 510 | 13 |

| SB60 | 120 | 1050 | 91 | HB700 | 104 | 940 | 49 |

| SB70 | 135 | 1200 | 117 | HB1G | 36 | 400 | 3 |

| SB80 | 140 | 1200 | 130 | HB2G | 45 | 460 | 4 |

| SB120 | 155 | 1450 | 193 | HB3G | 60 | 560 | 11 |

| SB121 | 155 | 1450 | 193 | HB5G | 75 | 650 | 20 |

| SB130 | 165 | 1500 | 227 | HB10G | 105 | 1000 | 65 |

| SB130-3 | 155 | 1500 | 185 | HB15G | 120 | 1000 | 80 |

| SB150 | 175 | 1600 | 272 | HB30G | 150 | 1300 | |

| SB160 | 175 | 1600 | 272 | F-1 | 36 | 400 | 3 |

| SH200 | 70 | 600 | 16 | F-2 | 45 | 480 | 5 |

| SH400 | 95 | 840 | 40 | F-3 | 52 | 520 | 8 |

| SH700 | 105 | 930 | 55 | F-4 | 60 | 540 | 11 |

| SH18G | 120 | 1110 | 85 | F-5 | 68 | 610 | 16 |

| SH20G | 135 | 1200 | 120 | F-6 | 75 | 720 | 23 |

| SH30G | 150 | 1300 | 157 | F-9 | 90 | 800 | 32 |

| SH35G | 140 | 1300 | 137 | F-12 | 105 | 1000 | 66 |

| SH40G | 160 | 1400 | 192 | F-19 | 120 | 1100 | 86 |

| SH50G | 180 | 1515 | 263 | F-22 | 135 | 1200 | 117 |

| SB30 | 53 | 580 | 9 | F-35 | 150 | 1400 | 169 |

| KRUPP | INDECO | ||||||

| HM130/131/135/140V | 65 | 780 | 18 | MES180/181/200 | 48 | 550 | 6 |

| HM300/301/305 | 80 | 900 | 30 | MES300/301/350/351 | 55 | 600 | 10 |

| HM170/185/190V | 75 | 800 | 25 | MES451/521/550/HB5 | 65 | 650 | 14 |

| HM550/560CS/V | 100 | 1000 | 55 | MES601/621/650 | 80 | 650 | 22 |

| HM700/720CS/V | 115 | 1080 | 82 | MES1200-HB12 | 90 | 800 | 34 |

| HM900/901/902 | 135 | 1150 | 115 | MES1500/HB19 | 110 | 900 | 55 |

| HM950/960/SC/V | 135 | 1080 | 110 | MES1750/1800 | 114 | 1000 | 72 |

| HM1300/1500CS/V | 150 | 1200 | 151 | MES121/150 | 45 | 480 | 5 |

| HM1800/2000CS/V | 160 | 1400 | 220 | MES2000/HB27 | 120 | 1000 | 78 |

| HM2200/2500CS/V | 180 | MES2500 | 130 | 1100 | 101 | ||

| HM45 | 42 | 470 | 6 | MES3000 | 140 | 1200 | 130 |

| HM50/55 | 45 | 480 | 7 | MES3500 | 145 | 1300 | 155 |

| HM60/75 | 55 | 590 | 10 | MES4000 | 150 | 1300 | 160 |

| HM85/90 | 62 | 600 | 11 | MES5000 | 160 | 1350 | 190 |

| HM100/101 | 65 | 700 | 18 | MKB | |||

| HM200 | 80 | 785 | 27 | MKB1300N | 135 | 1150 | 116 |

| HM400/401 | 80 | 800 | 27 | MKB1400 | 135 | 1150 | 116 |

| HM600/601 | 100 | 1000 | 55 | MKB2000 | 150 | 1250 | 156 |

| HM800 | 135 | 1150 | 115 | MKB2000N | 149 | 1250 | 154 |

| HM1200 | 120 | 1250 | 155 | MKB2500 | 160 | 1350 | 185 |

| GUANGLIN | MKB3000 | 165 | 1500 | 227 | |||

| SG1800 | 135 | 1200 | 120 | MKB4000N | 180 | ||

| SG2100 | 138 | 1250 | 125 | MKB100 | 45 | 450 | 5 |

| Mfano | Dia | Urefu | Uzito | Mfano | Dia | Urefu | Uzito |

| GUANGLIN | MKB | ||||||

| SG2500 | 145 | 1300 | 151 | MKB150 | 55 | 600 | 10 |

| SG2800 | 155 | 1450 | 190 | MKB200 | 65 | 600 | 14 |

| SG3200/3300 | 158 | 1500 | 200 | MKB300N | 70 | 750 | 20 |

| SG5000 | 180 | 1600 | 280 | MKB400 | 80 | 600 | 21 |

| SG200 | 45 | 500 | 5 | MKB500 | 80 | 600 | 21 |

| SG300 | 57 | 600 | 10 | MKB800 | 100 | 1000 | 55 |

| SG350 | 68 | 700 | 17 | MKB900N | 100 | 1000 | 55 |

| SG400 | 75 | 690 | 20 | MKB1200 | 115 | 1150 | 84 |

| MONTABERT | DAENO | ||||||

| BHR75/76/90/91 | 60 | 550 | 8 | DMB03 | 68 | 600 | 16 |

| BRP85/100 | 62 | 620 | 12 | DMB04 | 95 | 900 | 43 |

| BRP130/150 | 75 | 740 | 21 | DMB06 | 105 | 930 | 55 |

| BRV32 | 122 | 1100 | 90 | DMB4000 | 150 | 1450 | 181 |

| BRV43 | 150 | 1300 | 160 | DMB5000 | 165 | 1600 | 249 |

| BRV45 | 150 | 1300 | 160 | S150 | 57 | 600 | 10 |

| BRV52 | 162 | 1350 | 192 | S500 | 69 | 680 | 18 |

| BRV53 | 170 | 1400 | 230 | S900 | 85 | 830 | 33 |

| BRV55 | 170 | 1500 | 245 | S1300 | 105 | 926 | 56 |

| BRV1600 | 140 | S1800 | 120 | 1000 | 80 | ||

| BRH40 | 45 | 500 | 6 | S2200-1 | 130 | 1200 | 112 |

| BRH125 | 80 | 700 | 21 | S2000-2 | 135 | 1200 | 121 |

| BRH250/270 | 95 | 850 | 40 | S2500 | 140 | 1200 | 130 |

| BRH501/570 | 114 | 1000 | 76 | S3000/3600/4500 | 150 | 1350 | 168 |